Ensuring Accuracy and Reliability of Flow Meters: Calibration and Verification Procedures

- ADMIN

- Apr 27, 2023

- 2 min read

Flow meters play a critical role in many industrial processes, providing accurate and reliable measurements of liquid or gas flow rates. However, like any measurement instrument, flow meters require periodic calibration and verification to maintain their accuracy and reliability. In this article, we will discuss the importance of calibration and verification procedures for flow meters and provide guidance on the best practices for ensuring accurate and reliable measurements.

Calibration is the process of comparing the readings of a flow meter to a known standard, such as a NIST-traceable flow standard, to determine the meter's accuracy. Verification, on the other hand, is the process of checking the meter's performance under actual operating conditions to ensure that it is measuring within an acceptable level of accuracy. Both calibration and verification are critical to maintaining the accuracy and reliability of flow meters.

To ensure accurate measurements, flow meters should be calibrated at regular intervals, as specified by the manufacturer or based on the operating conditions and application. The calibration interval may vary depending on the type of flow meter, the measurement range, and the application. For example, a flow meter used in a critical application, such as custody transfer, may require more frequent calibration than a meter used in a less critical application.

The calibration procedure for flow meters may vary depending on the type of meter, but generally involves comparing the meter's output to a known flow standard at various flow rates. The results of the calibration should be documented and compared to the manufacturer's specifications or industry standards. Any discrepancies should be investigated, and the meter should be adjusted or repaired if necessary.

Verification procedures, on the other hand, involve checking the meter's performance under actual operating conditions. This may include checking for signs of wear or damage, such as corrosion or fouling, that could affect the meter's accuracy. The meter should also be checked for any changes in the flow rate or other operating conditions that could affect the measurement. Any deviations from the expected performance should be investigated and corrected.

In addition to calibration and verification, proper maintenance and handling of flow meters are also critical to maintaining their accuracy and reliability. Flow meters should be installed correctly, with proper grounding and alignment, and kept clean and free from debris or buildup. Regular inspections and preventative maintenance, such as cleaning or replacing sensors, can also help to ensure accurate measurements.

To summarize, calibration and verification are critical procedures for ensuring the accuracy and reliability of flow meters. Proper calibration procedures, based on manufacturer or industry standards, should be followed at regular intervals. Verification procedures should also be conducted to ensure the meter's performance under actual operating conditions. Regular maintenance and handling of flow meters are also essential to their accuracy and reliability.

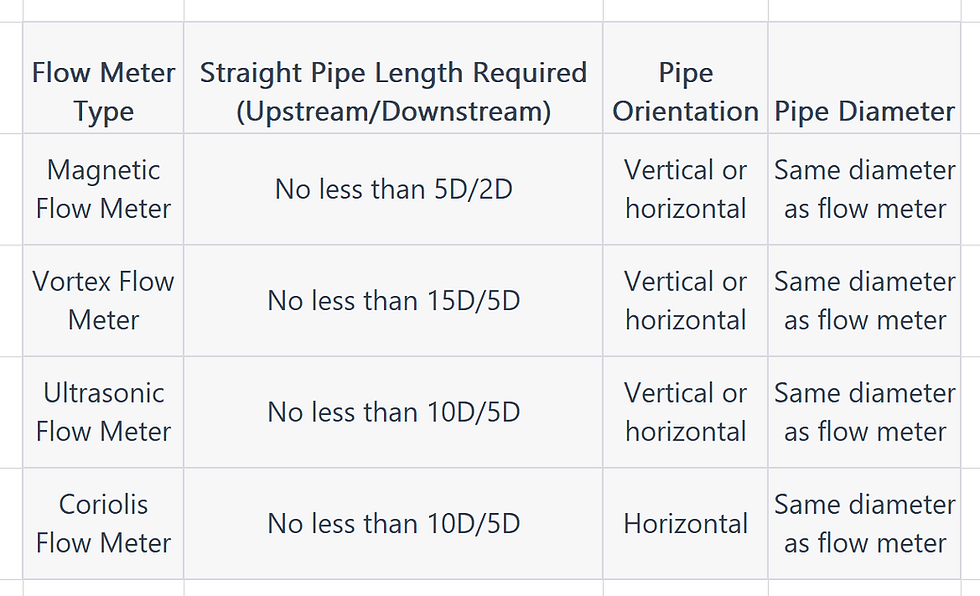

To help you understand the different calibration procedures for various types of flow meters, we have provided a comparison table below:

In conclusion, proper calibration and verification procedures are essential for ensuring the accuracy and reliability of flow meters. By following manufacturer or industry standards and conducting regular maintenance and inspections, flow meters can provide accurate and reliable measurements, improving the efficiency and safety of industrial processes.

Comments