Aircraft Corrosion Control – Lessons from the Sky and Prevention Strategies to Keep Fleets Airworthy

- ADMIN

- Aug 12, 2025

- 5 min read

Overview – When the Sky Opened Over Hawaii

On April 28, 1988, Aloha Airlines Flight 243 lifted off from Hilo, Hawaii, bound for Honolulu. It was a typical sunny island day, and passengers settled in for a short 35-minute hop. Just 23 minutes later, at 24,000 feet, the aircraft’s calm hum was shattered by a deafening boom. A massive section of the fuselage roof ripped away, leaving passengers staring into open sky and clinging to their seats as 300-knot winds roared through the cabin.

The Boeing 737-200 had logged over 89,000 cycles of short-haul island flights, constantly exposed to humid, salt-heavy air. Hidden beneath paint and sealant, corrosion had silently attacked the fuselage lap joints for years. Combined with metal fatigue, it finally gave way. The incident claimed one life and injured dozens, but could have easily killed everyone aboard.

This is the reality of corrosion in aviation: invisible, relentless, and potentially catastrophic. And it’s why aircraft corrosion control is not just a maintenance task—it’s a lifeline.

Table of Contents

Real-World Disasters – How Corrosion Has Changed Aviation Forever

How Corrosion Attacks Aircraft – Science, Types, and High-Risk Areas

Inspection, Prevention, and Control – From CPCPs to Field Practices

AVA AERO’s Role in Aircraft Corrosion Control Across the Middle East

Corrosion Control Cart Specifications – SCCC & LCCC Compared

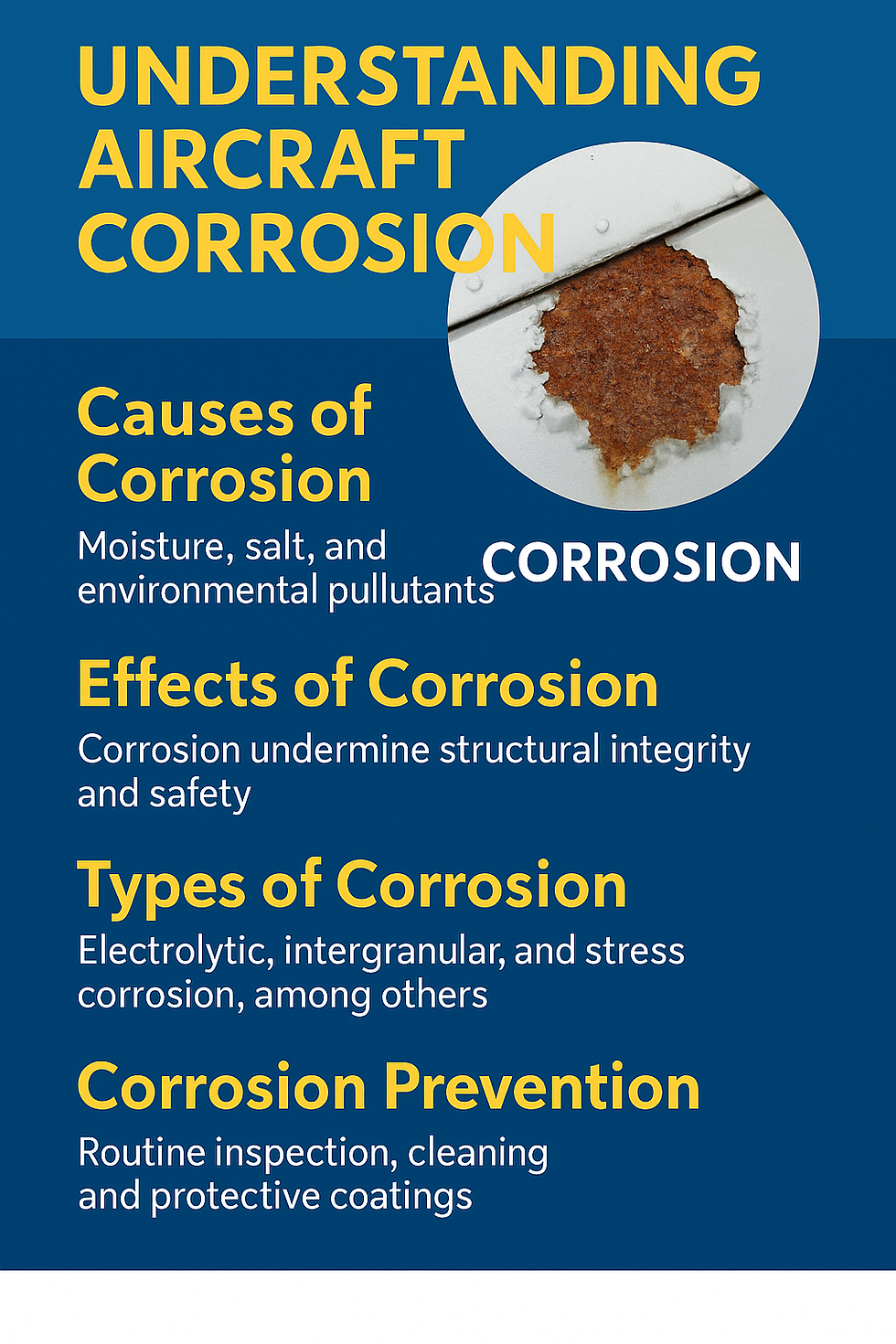

1. Understanding Aircraft Corrosion Control

Aircraft corrosion control refers to the strategies, procedures, and equipment used to prevent, detect, and treat metal degradation on airframes and components. It is a multidisciplinary effort involving:

Engineering design – choosing corrosion-resistant alloys and protective coatings.

Operational practices – minimizing environmental exposure.

Maintenance programs – regular inspections, cleaning, and treatment.

While modern aircraft use advanced materials such as aluminum-lithium alloys, titanium, and composites, most still rely heavily on aluminum for the fuselage and wings. Aluminum resists rust, but not pitting corrosion or galvanic reactions when in contact with dissimilar metals. Add moisture, salt, pollutants, and temperature cycling, and the result is a highly active corrosion environment.

In Middle Eastern conditions, additional risks include:

Salt-laden coastal air (UAE, Oman, Bahrain).

Dust and sand abrasion (Saudi Arabia, Kuwait).

High humidity during seasonal shifts.

Intense UV exposure that degrades protective coatings.

2. Why Corrosion is a Critical Safety and Economic Threat

Corrosion is not simply a matter of aesthetics—it’s a progressive weakening of structural and functional integrity. In aviation, that means:

Structural Safety – Thinning skins, cracked spars, and compromised fasteners can lead to in-flight structural failure.

System Reliability – Corroded hydraulic lines, electrical connectors, or fuel systems can cause malfunctions.

Economic Costs – Industry studies estimate corrosion accounts for up to 25% of direct maintenance costs for older fleets.

Regulatory Compliance – Authorities like the FAA and EASA require comprehensive Corrosion Prevention and Control Programs (CPCPs).

In the Middle East, where high-humidity coastal environments and sand-laden air accelerate degradation, aircraft corrosion control is especially critical for both civil and military fleets.

3. Real-World Disasters – How Corrosion Has Changed Aviation Forever

Aloha Airlines Flight 243 – 1988

Routine short hops in salt-rich air masked a ticking time bomb beneath the paint. Lap joint corrosion combined with high-cycle fatigue resulted in explosive decompression and structural loss mid-flight. This incident spurred FAA’s aging aircraft rules and made CPCPs mandatory.

China Airlines Flight 611 – 2002

Cruising at 35,000 feet, the Boeing 747-200 disintegrated over the Taiwan Strait. The root cause? An improperly executed tailstrike repair in 1980 that trapped moisture. Over 22 years, undetected corrosion and fatigue cracks spread until the structure failed catastrophically, killing all 225 aboard. This event reinforced the need for long-term corrosion monitoring after repairs.

Southwest Airlines Flight 2294 (2009) & Flight 812 (2011)

Two separate Boeing 737-300s experienced rapid decompression due to corrosion-assisted lap joint cracking. Although both landed safely, the incidents forced urgent fleet inspections and accelerated CPCP schedules for high-cycle aircraft.

These cases demonstrate one undeniable truth: corrosion doesn’t need decades to become dangerous—once it reaches critical thresholds, failure can be sudden and unforgiving.

4. How Corrosion Attacks Aircraft – Science, Types, and High-Risk Areas

Aircraft corrosion is essentially an electrochemical reaction where metal atoms oxidize in the presence of an electrolyte (usually moisture mixed with salts or pollutants). The reaction’s speed depends on:

Metal type

Surface protection

Environmental conditions

Mechanical stresses

Types of Aircraft Corrosion:

Type | Description | Common Locations |

Uniform Corrosion | Even metal loss across a surface | Landing gear legs, outer skins |

Pitting Corrosion | Localized deep holes | Wing skins, fuselage panels |

Crevice Corrosion | In moisture-trapped gaps | Lap joints, hinges |

Galvanic Corrosion | Between dissimilar metals | Steel fasteners in aluminum |

Stress Corrosion Cracking (SCC) | Cracks under stress and corrosion | Landing gear, mounts |

Filiform Corrosion | Worm-like tracks under paint | Painted panels, under decals |

High-Risk Zones:

Bilge areas (fluid collection points)

Wheel wells (water, de-icing fluid exposure)

Wing leading edges (impact and precipitation)

Cargo compartments (fluid leaks)

Control surface hinges (poor drainage)

5. Inspection, Prevention, and Control – From CPCPs to Field Practices

The FAA Corrosion Prevention and Control Program requires:

Identification of corrosion-prone areas.

Regular scheduled inspections.

Approved treatment and repair methods.

Comprehensive maintenance record-keeping.

Detection Methods:

Visual Inspection – First line of defense.

Borescopes – Inspecting internal cavities.

Eddy Current Testing (ECT) – Detecting cracks and corrosion below the surface.

Ultrasonic Testing (UT) – Measuring metal thickness loss.

Dye Penetrant Inspection (DPI) – Locating surface defects.

Prevention Practices:

Washing aircraft after exposure to salt, sand, or de-icing agents.

Applying corrosion inhibitors to high-risk areas.

Sealing lap joints and improving drainage.

Storing aircraft in controlled-humidity hangars.

Using purpose-built equipment like AVA AERO’s Corrosion Control Carts to clean and treat surfaces efficiently.

6. AVA AERO’s Role in Aircraft Corrosion Control Across the Middle East

AVA AERO is the exclusive distributor of Hydraulics International Inc. corrosion control equipment in the Middle East, providing advanced solutions tailored to regional conditions. Our corrosion control carts are designed for:

Ramp or hangar operation – Mobility where it’s needed most.

Large tank capacities – Extended operation without refills.

Precise pressure control – Effective cleaning without surface damage.

Multi-fluid capability – Water, cleaning solution, and air integration.

For operators in the UAE, Saudi Arabia, Oman, and the GCC, where salt air and high humidity accelerate degradation, our equipment is an essential tool for staying ahead of corrosion.

7. Corrosion Control Cart Specifications – SCCC & LCCC Compared

Feature | SCCC – Model A/M32M-40, P/N 051497-100 | LCCC – Model 051496-100 |

NSN | 4920-01-536-1924 | 4920-01-536-1925 |

Dimensions (L x W x H) | 58" x 45" x 42" | 86" x 60" x 52" |

Weight (Empty / Gross) | 1600 lbs / 2400 lbs | 2250 lbs / 3500 lbs |

Engine | Diesel, 9.8 HP, 401cc, air-cooled | Diesel, 9.8 HP, 418cc, air-cooled |

Fuel Tank | 3.7 gal | 3.7 gal |

Generator | 120/208 VAC, 3-phase, 60 Hz | 120/208 VAC, 3-phase, 60 Hz |

Water Tank Capacity | 75 gal | 200 gal |

Solution Tank Capacity | 10 gal | 25 gal |

Pressure Range | 0–110 PSI (60 nominal) | 10–110 PSI (60 nominal) |

Flow Rate | 0–8 GPM | Up to 8 GPM |

Air Pump | — | 8 SCFM @ 120 PSI |

Pump Type | — | Positive displacement gear (bronze) |

Motor | — | 2 HP, TEFC, 208/460 VAC, 3-phase |

Battery | 12V sealed dry cell, 220 CCA | 12V sealed dry cell, 800 CCA |

Tires | 4.80-8, 8 ply | 4.48-8, 8 ply |

Conclusion

Corrosion is the silent enemy of aviation safety. From the skies over Hawaii to the Taiwan Strait, history has shown that aircraft corrosion control is essential to prevent disaster. For Middle Eastern operators, the stakes are even higher due to the harsh environmental conditions that accelerate degradation.

AVA AERO’s SCCC and LCCC Corrosion Control Carts give MRO teams the ability to combat corrosion efficiently, meet CPCP requirements, and extend aircraft life while ensuring safety and compliance.

By investing in the right equipment, operators are not just protecting assets—they’re protecting lives.

Comments